What are the different types of touch screens?

In today's digital age, touch screens have become an essential part of our daily lives. From smartphones and tablets to kiosks and industrial equipment, touch screens are everywhere. They provide a more intuitive and user-friendly interface, allowing us to easily navigate through various applications with just a touch of a finger.

When it comes to industrial touch screens, there are several different types that are commonly used for specific applications. Each type of touch screen has its own unique features and benefits, making them suitable for different environments and use cases. In this article, we will explore different types of touch screens commonly used in industrial settings.

1. Resistive Touch Screens:

Resistive touch screens are one of most common types of touch screens used in industrial applications. They consist of two layers of conducting materials separated by a small gap. When pressure is applied to screen, two layers come into contact, allowing device to detect touch. Resistive touch screens are durable and cost-effective, making them popular for industrial applications where reliability and affordability are key considerations.

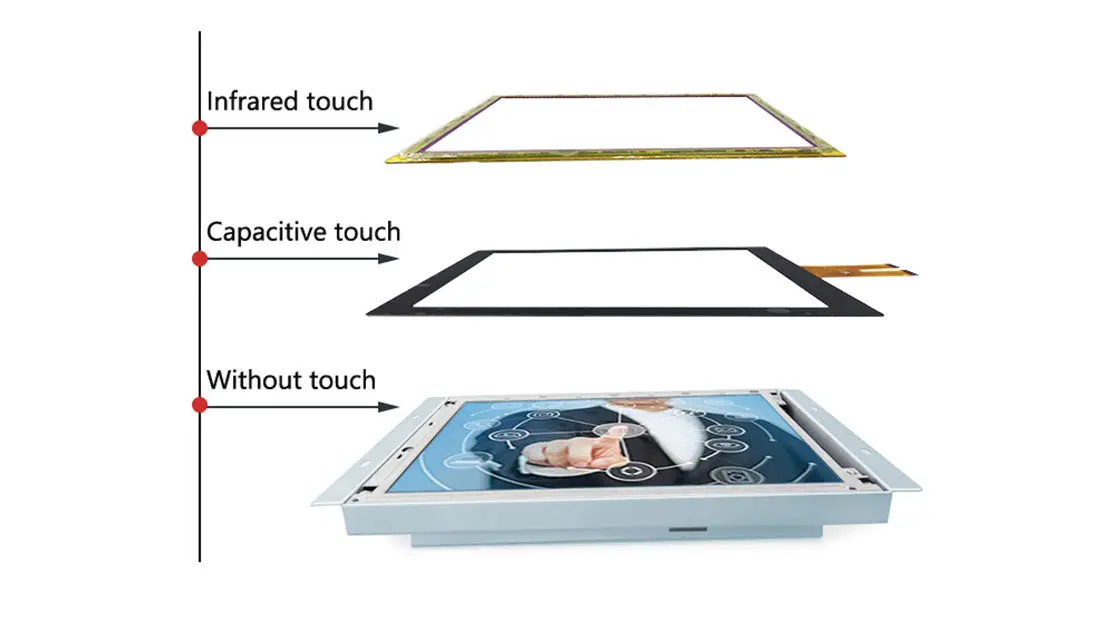

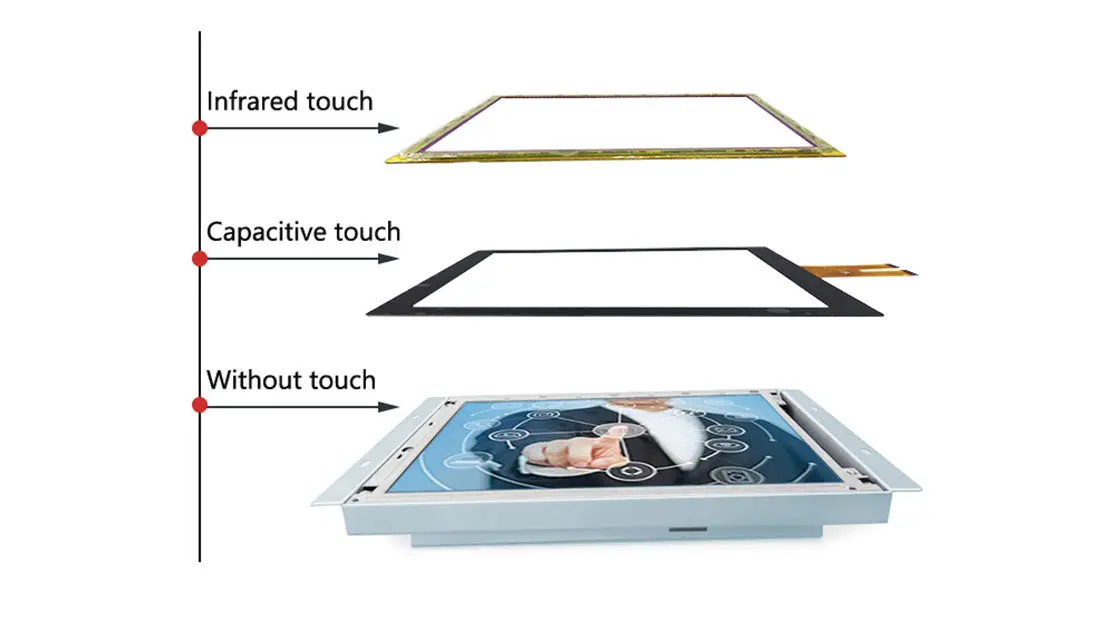

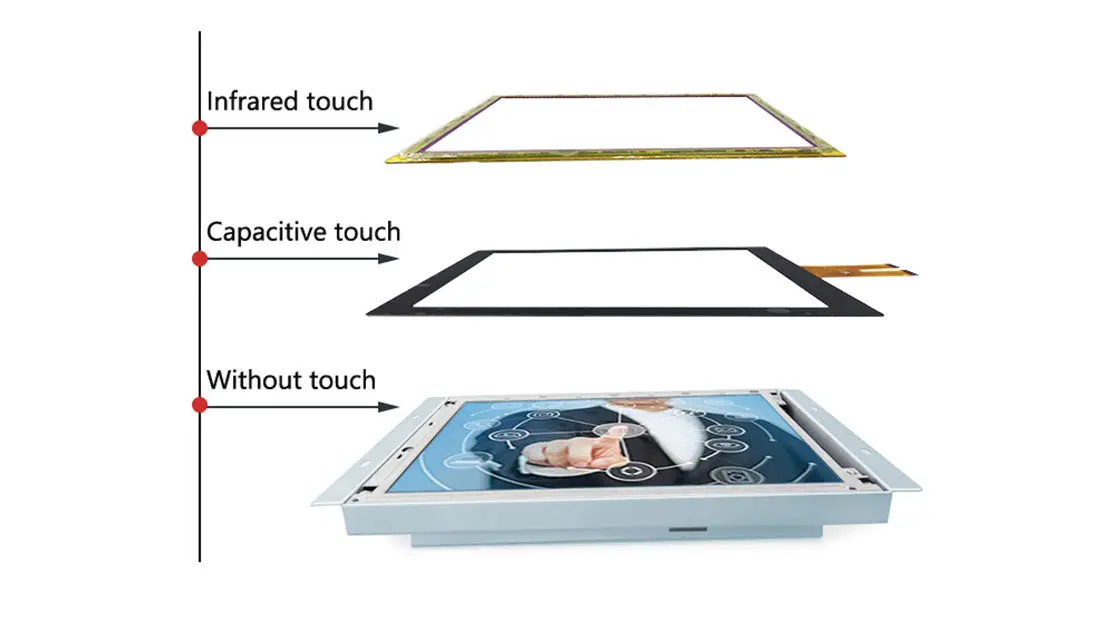

2. Capacitive Touch Screens:

Capacitive touch screens are another popular type of touch screen used in industrial settings. Unlike resistive touch screens, capacitive touch screens work by detecting changes in electrical charge when a conductive object, such as a finger, comes into contact with screen. Capacitive touch screens offer better clarity and responsiveness compared to resistive touch screens, making them ideal for applications where precision and speed are important.

3. Infrared Touch Screens:

Infrared touch screens use an array of infrared LED lights and sensors to detect touch input. When a finger or other object touches screen, it interrupts infrared light beams, allowing device to determine touch location. Infrared touch screens are highly durable and can withstand harsh industrial environments, making them suitable for applications that require ruggedness and reliability.

4. Surface Acoustic Wave Touch Screens:

Surface acoustic wave touch screens use ultrasonic waves to detect touch input. When a finger touches screen, it creates surface waves that are detected by sensors located on edge of screen. Surface acoustic wave touch screens offer excellent clarity and image quality, making them ideal for applications that require high-definition displays.

In conclusion, industrial touch screens come in various types, each offering unique features and benefits for different applications. Whether you need a rugged and durable touch screen for harsh industrial environments or a high-precision touch screen for intricate tasks, there is a type of touch screen that is suitable for your needs. By understanding different types of touch screens available, you can choose best option for your specific industrial application.

Leave a Reply