What is the significance of computers in industrial manufacturing?

Computers have become an integral part of industrial manufacturing processes, revolutionizing way products are designed, produced, and assembled. They have significantly increased efficiency, accuracy, and productivity in manufacturing operations, leading to improved quality and reduced costs. In this article, we will explore significance of computers in industrial manufacturing and how they have transformed industry.

One of key roles that computers play in industrial manufacturing is in product design and development. Computer-aided design (CAD) software allows engineers and designers to create and modify product designs with precision and efficiency. This not only speeds up design process but also enables creation of more complex and innovative products. CAD software also allows for simulations and prototyping, which helps identify potential issues early on in design process, saving time and money.

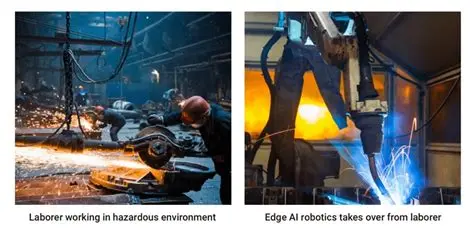

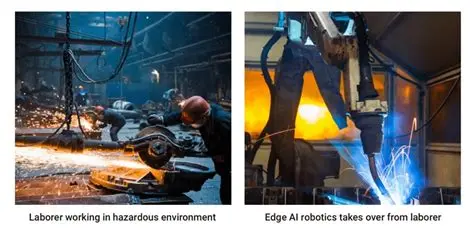

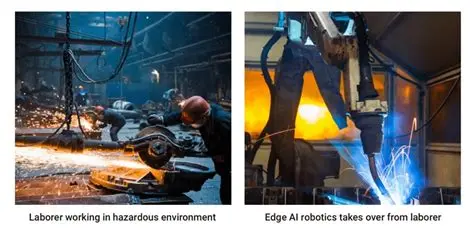

Once product design is finalized, computers are used in manufacturing process itself. Computer-aided manufacturing (CAM) software is used to program machines such as CNC (computer numerical control) machines, robots, and 3D printers to produce designed products. These machines are capable of performing tasks with a high degree of accuracy and repeatability, leading to consistent quality in finished products. Computers also control flow of materials and components throughout manufacturing process, optimizing efficiency and minimizing waste.

In addition to product design and manufacturing, computers are also used in quality control and inspection. Automated inspection systems use computer vision technology to detect defects or inconsistencies in products, ensuring that only high-quality products reach market. Computers can also analyze data from sensors and machines in real-time to monitor production process and make adjustments as needed to maintain quality standards.

Another significant role that computers play in industrial manufacturing is in inventory and supply chain management. Through use of enterprise resource planning (ERP) systems, companies can track inventory levels, forecast demand, and manage procurement and distribution processes efficiently. This helps companies streamline their operations, reduce costs, and improve customer satisfaction by ensuring that products are delivered on time.

Overall, significance of computers in industrial manufacturing cannot be understated. They have revolutionized industry by increasing efficiency, accuracy, and productivity in all aspects of manufacturing process. From product design to quality control to supply chain management, computers play a crucial role in ensuring that companies can produce high-quality products in a cost-effective and timely manner. As technology continues to advance, the role of computers in industrial manufacturing will only continue to grow, further shaping the future of the industry.

Leave a Reply