How are industrial computers used in metal processing?

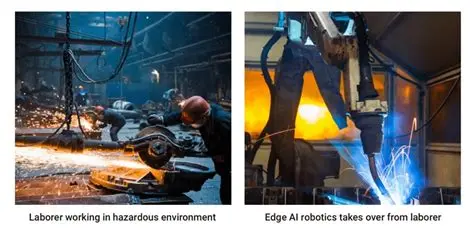

In today's fast-paced world, industrial computers play a crucial role in various industries, including metal processing. These specialized computers are designed to withstand harsh environments, high temperatures, and vibrations, making them ideal for use in manufacturing facilities where metal processing takes place.

Industrial computers are used in metal processing for a wide range of applications, from controlling production process to monitoring equipment performance and ensuring quality control. These computers are equipped with powerful processors, ample memory, and rugged enclosures to ensure reliable and efficient operation in industrial settings.

One of key ways industrial computers are used in metal processing is through control of automated machinery. These computers can be programmed to execute a series of commands that govern operation of machines such as CNC (computer numerical control) lathes, mills, and routers. By using industrial computers to control these machines, manufacturers can ensure precise and accurate processing of metal parts, leading to improved productivity and quality.

Industrial computers are also used in metal processing for monitoring equipment performance and collecting real-time data on production processes. These computers are often connected to sensors and monitoring devices that track various parameters such as temperature, pressure, and speed. By collecting this data, manufacturers can analyze and optimize their production processes, identify potential issues, and make informed decisions to improve efficiency and reduce downtime.

Furthermore, industrial computers are used in metal processing for quality control purposes. These computers can be equipped with vision systems and inspection software that analyze surface finish, dimensions, and other characteristics of metal parts. By using industrial computers for quality control, manufacturers can ensure that their products meet strict specifications and standards, leading to higher customer satisfaction and reduced scrap and rework.

In conclusion, industrial computers play a critical role in metal processing by controlling automated machinery, monitoring equipment performance, and ensuring quality control. These rugged and reliable computers are essential for improving productivity, efficiency, and quality in manufacturing facilities where metal processing takes place. As technology continues to advance, industrial computers will undoubtedly play an even greater role in shaping future of metal processing and other industrial sectors.

Leave a Reply