Learn more about industrial computers

Industrial computers or PCs are designed and built to handle complex industrial tasks. Made with industrial-grade components and rugged housings, and rigorously tested for reliability, industrial PCs excel in environments where regular desktop computers cannot. Basic features of industrial PCs include:

vent-free and fanless design, ability to withstand vibration and harsh environments, easy configuration, comprehensive I/O options, extended lifecycle, durable components.

Understanding how to choose an industrial PC for your application is critical to improving the productivity and efficiency of your facility. Learn more about the main types of PCs, considerations when choosing a PC for your facility, key benefits, typical applications, and more.

Common Types of Industrial PCs

There are three main types of industrial PCs, all with integrated touch displays.

Industrial Panel Computers (IPPCs)

IPPCs are considered the most rugged type of industrial PCs and are ideal for heavy-duty industrial applications such as automotive, steel manufacturing, dairy, and meat processing plants. These computers are equipped with capacitive or resistive touch sensors and can be operated by personnel wearing gloves. Capable of handling the most environmentally challenging applications, IPPCs are the most I/O-intensive of all industrial PC types and feature: installed I/O cards, redundant array of independent disks (RAID) and ports, multiple drives, PCI/PCIe expansion slots.

Panel PCs (PPCs)

Designed for a variety of light industrial tasks, the most affordable type of industrial PC with ample input and output expansion options. Screen options include widescreen with multi-touch or standard 4:3 with resistive touchscreen. Sizes range from 6.5 inches to 42 inches.

Touchscreen PCs (TPPCs)

Designed for standard industrial applications, TPPCs are fanless, SCADA-enabled, slim-profile, and thin-client terminals. Screen sizes range from 6.5 inches to 42 inches. These rugged devices come in cast aluminum housings and run on Android or Windows operating systems. TPPCs typically have the fewest available I/Os compared to other types of industrial PCs. Depending on the needs of the specific application, industrial computers can have the following features and mounting options: fully enclosed, wall-mounted, wall-mounted, VESA mount, swing arm, fold down, desktop mount. Materials Industrial computer housings and displays are constructed of a variety of materials, including: 1. Housing: aluminum, stainless steel, carbon fiber or composite. 2. Display: polycarbonate, glass, lexan. How to Choose an Industrial Computer When choosing an industrial computer for your application, consider the required computing performance, operating environment, available power, space constraints and connectivity capabilities. This article focuses on considerations, key benefits, typical applications, and more when selecting a computer for your facility. Here is an overview of the options you need to choose.

Mounting

There are a variety of mounting styles to choose from: articulated swing arm, wall-mounted, wall-mounted, VESA mount, VESA arm, desktop, stand, rack mount, panel mount

Processor (CPU)

The central processing unit (CPU) follows the instructions of a computer program to process, store and calculate data. As the brain of the computer, the CPU must meet the specific needs of its intended application.

Environment

Depending on your needs, you can choose from the following types of industrial PCs: Harsh or rugged, protected or non-rugged, hazardous areas.

Application/Industry Use

Industrial computer systems are used in a wide range of industries and applications, including but not limited to: Aerospace and Defense, Air Traffic Control, Automotive, Flight Simulation, Food Processing, Life Sciences, Machine Tools, Marine, Oil and Gas, Packaging, Paints and Coatings, Petrochemical, Pulp and Paper, Rubber and Plastics, Transportation.

Connections

Depending on your application, choose from standard or specialized connections: 1. Standard: USB, CAT-5 Network, Secure, Dustproof.

2. Specialized: Hot-swappable connectors, Hazardous Area, Military.

Operating Systems

Industrial computers are compatible with Windows, Linux or PLC operating systems.

Display Size

The display screens of industrial computers vary depending on the type of device, with the following size options: 6.5-inch, 10.4-inch, 12.1-inch, 15-inch, 15.6-inch, 17.3-inch, 19-inch, 20.1-inch, 21.5-inch, 24-inch, 27-inch, 42-inch.

Key Features and Benefits

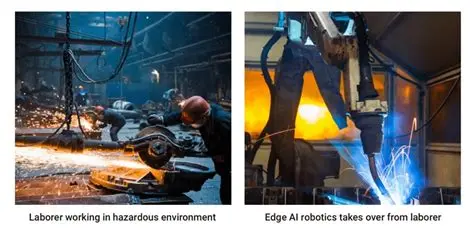

The main benefit of industrial computers is that they can operate in harsh, unstable environments where regular desktop computers cannot. Industrial computers can withstand these conditions because they are carefully designed and constructed to: l Operate in extreme heat and cold l Resist vibration and shock l Resistant to debris and dust due to fanless design

ApplicationsManufacturing

Many commercial and industrial manufacturers rely on industrial computers for robot guidance and machine vision. Industrial computers can also collect data from equipment and machinery to implement preventive maintenance processes. Package Inspection and Quality Control Package inspection and machine vision systems enable food packaging plants and other manufacturers to automate quality control processes, thereby increasing efficiency and productivity.

Asset Tracking

The healthcare and retail industries use industrial PC hardware in their daily operations to track and monitor processes and assets for any anomalies or inconsistencies.

Simulation & Control

With powerful processors, industrial PCs can create and simulate real-world scenarios to gain insights into: Analyze potential risks Predict future possibilities Test systems in any framework Remote Data Management Remote Internet of Things (IoT) sensors can send and receive data related to the use of remote devices, hardware, tools, and other connected devices. Machine operators can deploy sensors to collect actionable data on equipment fatigue, operational processes, and overall performance.

Chemical, Pharmaceutical, and Food Processing

Industrial computers can operate reliably in hazardous areas where flammable vapors and chemicals are present. They can be decontaminated to ensure safety in these volatile environments. Industrial PCs are typically sterile and can be high pressure cleaned for use in sterile environments.

Leave a Reply